In our industry discussions tend to range from the low-tech to the high – from racking and shelving to the latest advances in picking technologies and robotics. But we don’t often discuss how those two ends of the spectrum are brought together through Radio Frequency Identification (RFID).

If the software in your Warehouse Management System (WMS) is considered the brain of your operations, then RFID is what’s known as Broca’s area of your brain. It’s the part that enables communication between the low- and high-tech pieces of your operations to work together.

We recently met with John Martinez, the Director of Sales for RFID Inc., the oldest, still active, global RFID manufacturer, to get his thoughts on what the industry should understand about RFID.

Teaching robots to read

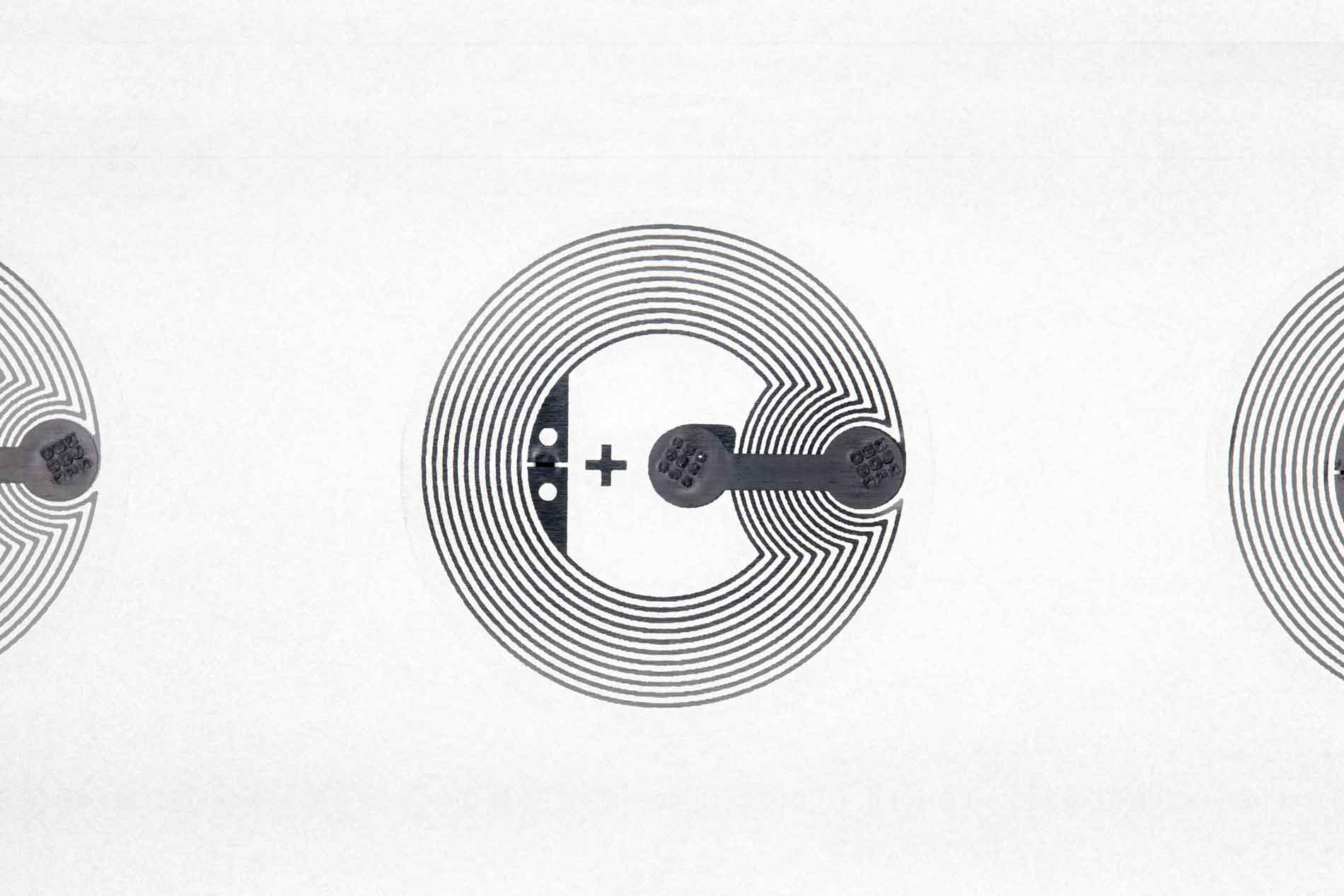

Every RFID has two main components – the tag (a reprogrammable computer chip) and the reader (which detects and decodes the tag). Widely used in the pharmaceutical industry – with the reader at a pill dispenser and a tag on every bottle, hundreds of different prescriptions can be refilled in a matter of minutes with zero error – RFID can be incorporated anywhere two parts of a WMS need to identify each other.

More accurate than humans, RFID technology is also incredibly fast. For warehouses with aggressive schedules, RFID technology is able to instantly count hundreds of different tags on multiple pallets moving through a single dock door at the same time. This combination of speed and accuracy can be the difference between keeping up with the leading competition and following a competitive leader.

The ROI on RFID: from less equipment to better maintenance scheduling

While the initial calculation for ROI may seem complex – a system might require many RFID readers to be installed on the same piece of equipment, or fewer readers might need to be installed at strategic locations throughout a large facility – RFID can save you money in some big ways.

Facilities have, for example, replaced multiple robots with a single robot equipped with an RFID reader. As different items come down the line, that robot can scan those items and know how differently each one needs to be treated, such as:

- Different carburetors being installed on different car models

- Oddly shaped or delicate pieces of merchandise that need to be boxed in a specific way or in a specific order

- Surgical supplies, medical instruments, pharmaceuticals, or other healthcare products that need to be packed precisely and shipped to the appropriate customer

- etc.

These facilities not only saved money on the various machines they no longer needed, but they also saved on the cost of all the square feet those many machines no longer took up.

RFID assisted fulfillment in an automated dry cleaning facility

RFID is also a tremendous tool in loss prevention. They can be used to track merchandise or assets moving through a facility or between multiple facilities. Assets, equipped with tags, can be tracked throughout a facility with readers installed at strategic checkpoints. And those same assets can then be tracked as they move out the dock door to another facility.

Maintenance is another area where RFID can play a crucial role. By tracking how often a piece of equipment is used, the system can know when it needs to be serviced. Much like the oil light on a car, this takes away from the user the need to track these things manually.

Different frequencies and packaging for different uses

There are many kinds of tags and readers, each with different uses and costs. Their operational distance varies from just a few feet to hundreds of meters. They can be “active” – sending out a ping every few minutes to any reader in the area. Or they can be “passive” – activated by the radio signal that the reader sends out. They can be thinly coated in paper or plastic and meant only to operate in climate-controlled warehouses, or they can be robustly protected and able to work in wet, caustic, or high-temperature environments.

The options of RFID are boundless, and their use could transform how our industry begins to streamline its operations to drive up order accuracies and cost savings.