Imagine you’re a surgeon. You’re in the middle of an operation and need an instrument, but when your nurse reaches for it on your prepackaged surgical tray, it isn’t there. Worse yet, imagine being that surgeon’s patient.

In material handling, doing our jobs well – and with precision – is critical to our customers.

We recently talked to Travis Motz, with our partner The Scale People, about how their scales can play an important role in ensuring accuracy in fulfillment and delivery.

The right weight to cut errors and save freight

The goal of material handling is to get the right product to the right people at the right time, and in the right condition. In the real-life case of prepackaged surgical trays, accuracy can be the difference between life and death; customers have to know that their packages are right when they leave our clients’ doors.

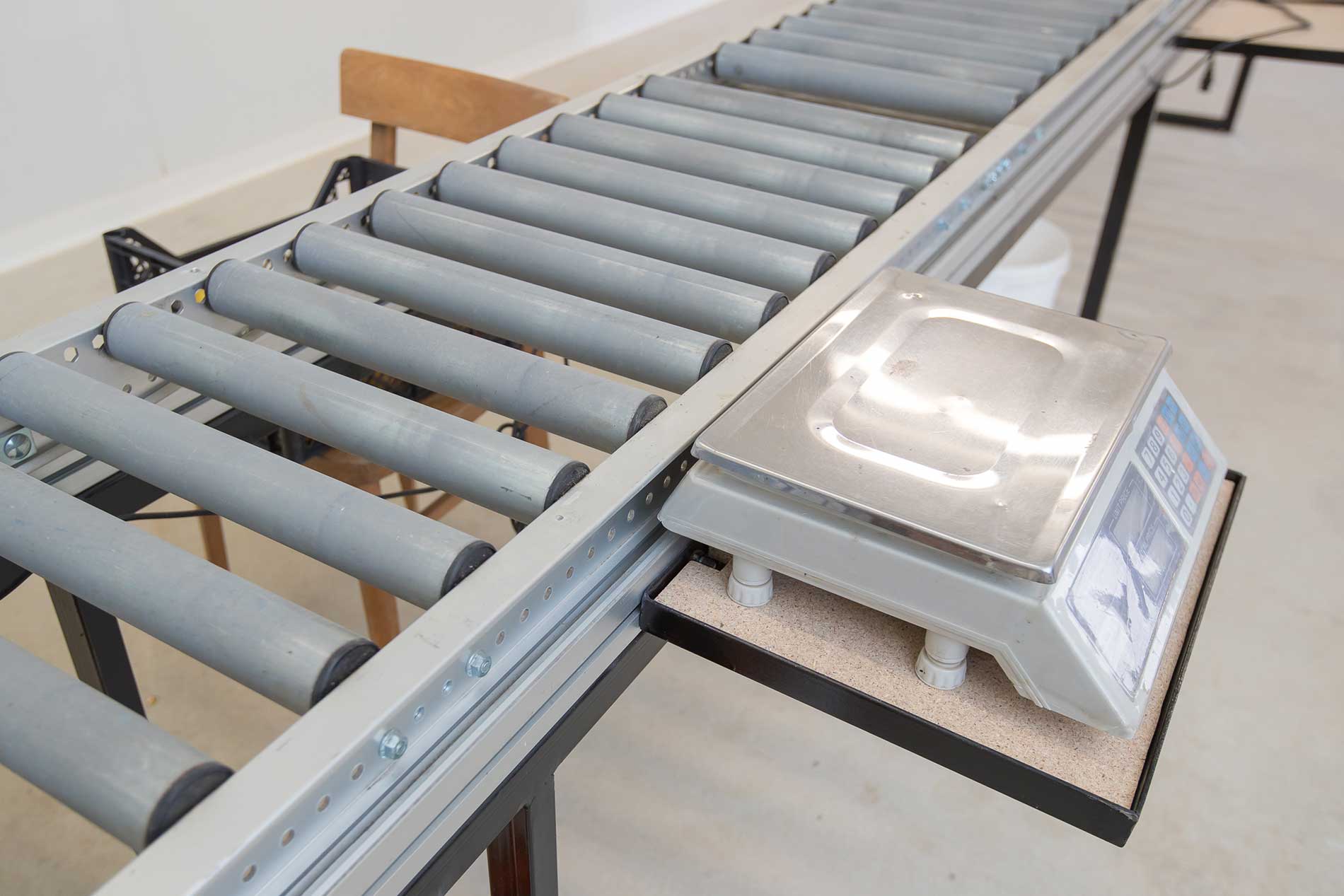

Integrating the right equipment into our clients’ distribution operations can significantly decrease their error rates. In our case with surgical-trays, The Scale People were able to install in-motion checkweighers into the conveyor system. These enabled packages to be weighed without ever stopping or even slowing down the system. Packages that register an improper weight can be automatically diverted for manual review, helping to eliminate the risk of faulty shipments.

The technologies of weighing and measuring have benefits beyond ensuring the integrity of a package’s contents. Your shipping and freight costs can benefit from precision, too. We’ve seen many clients vastly reduce their shipping costs by integrating scales into their fulfillment process, as demonstrated by a recent integration with Merit Medical.

Photo Credit: The Scale People, OEM Weighing Kit

The many scales of efficiency

In the modern era of big data, machine learning, and smart systems, perhaps the single most important thing any business can do to stay competitive is improve its efficiencies. And The Scale People do that in some innovative ways. For example:

- Fork Truck Scales: End the bottleneck of forktrucks waiting for floor scales by making your forklifts the scale. Able to be installed onto a forklift in minutes, these wireless scales instantly weigh whatever they lift, and send that information via Bluetooth to a display in the driver’s cab or directly to the warehouse control system (WCS).

- Drum Scales: Drum scales and barrel weighers are able to take 55-gallon drums – up to 2,500 lbs. – and not only weigh them, but also allow an operator to roll them across a warehouse for storage or shipping.

- Explosion Proof Scales: Safe for hazardous environments and easy to clean, explosion proof scales can be designed for use in automated processes or as stand-alone workstations.

- High Precision Bench and Platform Scales: These scales come in a wide variety, and can be used in checkweighing, counting, or washdown applications.

- Load Cells: Able to measure divisions of up to 1-part in 30,000, these load cells can be used in applications such as mixing, where they are installed under a silo. Because of their sensitivity, they are able to detect and validate small amounts of added ingredients without the need to stop mixing – all but eliminating bad batches.

Precise enough for jewelry, rugged enough for jets

From bench scales that measure as little as a thousandth of a gram to cabled weighing systems for 600,000 lb. airplanes, The Scale People have an instrument for any need. Having been in business since 1956, The Scale People have partnered with material handling integrators on innumerable projects. This experience allows them to approach a new client in any industry and understand how strategic placement of scales in fulfillment processes can help ensure accuracy and precision.